Cylindrical roller bearings are essential components in various industrial applications, providing support for rotating shafts while accommodating high radial loads. These bearings offer several key features and benefits that make them indispensable in a wide range of machinery and equipment. In this article, we will explore the main characteristics and advantages of cylindrical roller bearings.

High Load Capacity

One of the primary features of cylindrical roller bearings is their ability to withstand high radial loads. The design of these bearings allows for efficient distribution of load across the length of the rollers, enabling them to support heavy loads without deformation or damage. This high load capacity makes cylindrical roller bearings suitable for applications involving heavy machinery, such as construction equipment, industrial gearboxes, and large motors.

Precise Alignment

Cylindrical roller bearings are designed to maintain precise alignment between the rotating shaft and the stationary components. The parallel arrangement of the rollers enables accurate positioning, ensuring smooth and efficient operation of the machinery. This precise alignment capability is particularly crucial in precision equipment such as machine tools, where any misalignment could lead to performance issues or premature wear.

Enhanced Rigidity

Another notable benefit of cylindrical roller bearings is their enhanced rigidity, which contributes to improved performance and reliability of the equipment. The robust construction of these bearings, combined with their advanced design features, results in greater resistance to deflection and deformation under load. As a result, machinery equipped with cylindrical roller bearings can maintain stability and operational integrity even in demanding conditions.

Low Friction

Cylindrical roller bearings are engineered to minimize friction during operation, reducing energy consumption and heat generation within the machinery. The optimized internal geometry and surface finish of the bearing components contribute to lower frictional forces, promoting efficiency and extending the service life of the equipment. This low-friction characteristic is particularly advantageous in high-speed applications, where energy efficiency is a priority.

Easy Installation and Maintenance

With their simple and straightforward design, cylindrical roller bearings are relatively easy to install and maintain, saving time and effort for equipment operators and maintenance personnel. The standardized dimensions and mounting features of these bearings facilitate quick and hassle-free installation, while their robust construction minimizes the need for frequent maintenance interventions. This ease of installation and maintenance contributes to overall cost savings and operational efficiency.

Versatility and Adaptability

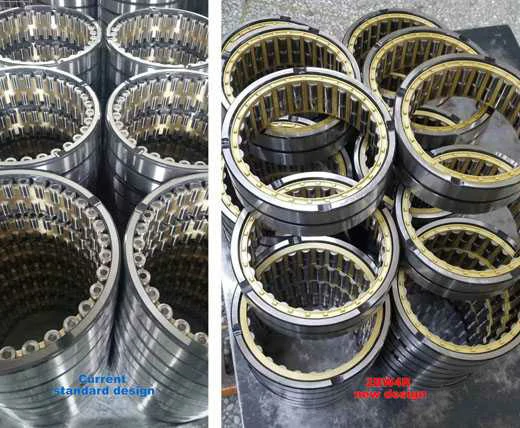

Cylindrical roller bearings are available in various configurations and designs, allowing for versatility and adaptability to diverse application requirements. Whether it’s single-row, double-row, or multi-row cylindrical roller bearings, or different cage designs and materials, there are options to suit specific performance and load-bearing needs. This versatility enables equipment designers and manufacturers to optimize the bearing selection for maximum efficiency and performance.

In conclusion, the key features and benefits of cylindrical roller bearings, including high load capacity, precise alignment, enhanced rigidity, low friction, easy installation and maintenance, and versatility, make them essential components in a wide range of industrial machinery and equipment. Their ability to withstand heavy loads, maintain accuracy, reduce friction, and adapt to varying application conditions contributes to the overall reliability, efficiency, and longevity of the equipment in which they are employed.

.webp)