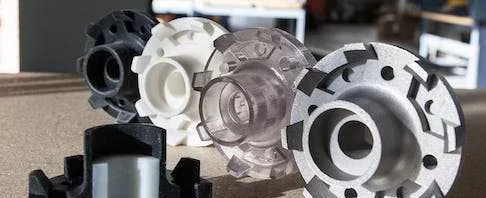

Polyjet produces parts with good surface finishes in a range of different colors and material types whereas SLS tends to have rough matte finishes with limited colors.

Inkjet vs. Laser Technology: Technology Comparison

Inkjet 3D printing technology is based on paper printing technology. It works by depositing multiple dots of plastic onto a build platform. A UV light is then used to cure the plastic before the next layer is applied. In some cases, a roller needs to flatten the layer before the next one is printed. Laser technology like SLS (Selective Laser Sintering), on the other hand, uses a laser as a heat source to fuse plastic particles. Alternatively, a UV laser is used in SLA (Stereolithography) printers to print with photopolymers.

Inkjet vs. Laser Technology: Material Comparison

Inkjet style printers either make use of just photopolymers as is the case with polyjet or they can use food, binding agents, or even cultured cells. These photopolymers can be rigid, clear, elastomeric, or specially formulated to mimic the properties of some thermoplastics like ABS. Other inkjet-style printers make use of a combination of a photopolymer binder with a thermoplastic powder base, typically nylon. Multi-jet printing is an example of this.

Laser printers typically print with thermoplastic powders. These printers fuse them by sweeping a laser across a thin layer of plastic powder to fuse the particles into the shape of the part layer.

Inkjet vs. Laser Technology: Product Applications Comparison

Inkjet printers, including polyjet, are primarily used for functional multi-material and multicolor prototypes. Inkjet parts are also used for more practical applications like dental molds, lenses, seals, and surgical aids but are not suited to hard-wearing industrial applications like gears, for example.

Powder fusion bed laser technologies can print in more functional materials like nylon and even metal. This allows for the manufacture of end-use parts as opposed to just prototypes. This technology cannot print in multiple colors or materials.

Inkjet vs. Laser Technology: Print Volume Comparison

Both inkjet and laser technologies can print large build volumes and are intended for series production. The largest polyjet inkjet printer has a build volume of 1 x 0.8 x 0.5 m. Selective laser sintering machines have somewhat smaller build volumes, 0.55 x 0.55 x 0.75 m.

Inkjet vs. Laser Technology: Surface Finish Comparison

Inkjet technologies can produce parts with very smooth surface finishes. This is why they are so well suited for one-off functional prototypes. Laser-based printing technologies produce parts with a matte finish. The surface of a laser-printed part is also difficult to post-process if coloring is required and can only be colored by dying it.

Inkjet vs. Laser Technology: Cost Comparison

Inkjet 3D printers make use of specialized photopolymers that can cost up to $500 per kg. Laser technology like SLS makes use of thermoplastic powders, which are much cheaper to produce, and cost only $50 per kg, on average.

.webp)